The Ultimate Guide to Plastic Cable Carrier Systems (2026 Edition)

In modern automation and motion systems, plastic cable carrier solutions are essential for protecting cables, hoses, and lines in dynamic applications. Whether you’re designing CNC machinery, packaging equipment, robotics, or industrial automation systems, choosing the right plastic cable carrier can significantly increase uptime and reduce maintenance costs.

In this guide, you’ll learn:

- What a plastic cable carrier is

- Key benefits compared to metal alternatives

- Common industrial applications

- How to choose the right model

- Installation and maintenance best practices

What Is a Plastic Cable Carrier?

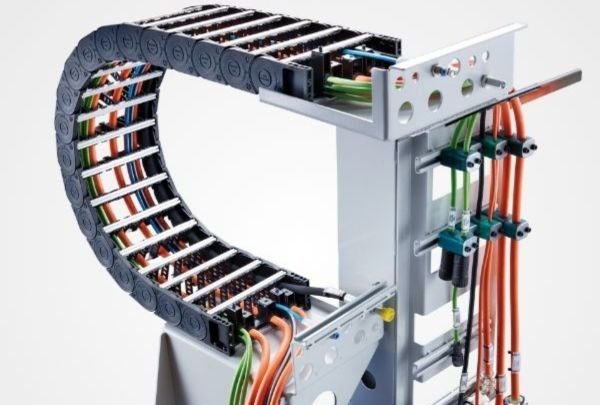

A plastic cable carrier (also known as an energy chain or drag chain) is a flexible guiding system designed to safely route and protect cables and hoses in moving machinery.

It prevents:

- Cable tangling

- Excessive bending

- Abrasion and wear

- Downtime caused by cable failure

Plastic cable carriers are typically made from reinforced engineering polymers such as nylon or glass-fiber-reinforced plastic, offering durability with low weight.

Why Choose a Plastic Cable Carrier Over Metal?

While metal cable carriers are used in heavy-duty environments, plastic cable carriers are often the preferred solution due to their performance-to-cost ratio.

1. Lightweight Construction

Plastic carriers reduce the moving mass of machinery, improving energy efficiency and lowering drive stress.

2. Corrosion Resistance

Unlike steel systems, plastic cable carriers resist moisture, chemicals, and harsh industrial environments.

3. Low Noise Operation

Plastic materials absorb vibration better, making them ideal for automation environments where noise reduction is important.

4. Lower Maintenance Costs

Self-lubricating polymers reduce wear and eliminate the need for lubrication.

Common Applications of Plastic Cable Carriers

Plastic cable carrier systems are widely used across industries:

CNC Machinery

High-speed movement requires controlled cable guidance to avoid costly breakdowns.

Industrial Automation

Robotic arms and automated assembly lines depend on reliable cable management.

Packaging Equipment

Continuous motion systems require durable cable routing.

Medical Technology

Clean environments benefit from corrosion-resistant, lightweight plastic carriers.

Material Handling

Conveyors and lifting systems rely on safe cable routing under dynamic loads.

Key Factors When Selecting a Plastic Cable Carrier

Choosing the right plastic cable carrier ensures optimal performance and longevity.

1. Bend Radius

Select a carrier that matches the minimum bend radius of your cables.

2. Inner Height & Width

Ensure sufficient space for all cables and hoses — overcrowding leads to premature failure.

3. Travel Length

For long travel distances, consider glide systems or support rollers.

4. Load Capacity

Calculate cable weight per meter and ensure the carrier supports the load.

5. Environmental Conditions

Consider temperature range, chemical exposure, and debris levels.

Installation Best Practices

To maximize lifespan:

- Avoid overfilling the carrier

- Separate cables using dividers

- Secure cables at both ends

- Allow for free movement inside the chain

- Perform routine inspections

Improper installation is one of the most common causes of premature cable carrier failure.

Maintenance Tips for Long-Term Performance

Plastic cable carriers require minimal maintenance, but routine checks are recommended:

- Inspect for cracked links

- Check mounting brackets

- Remove debris buildup

- Replace worn cables immediately

Preventive maintenance reduces unexpected downtime and extends system life.

Future Trends in Plastic Cable Carrier Technology

As automation advances, plastic cable carrier systems continue to evolve:

- High-speed applications with reduced vibration

- Modular designs for quick installation

- Smart monitoring integration

- Advanced polymer blends for extreme environments

The demand for lightweight, durable, and maintenance-free cable management systems continues to grow in 2026 and beyond.

Conclusion: Is a Plastic Cable Carrier the Right Choice?

If your application involves repetitive motion, precision machinery, or automated systems, a plastic cable carrier offers:

- Cost-effective cable protection

- Improved machine reliability

- Reduced downtime

- Long service life

Selecting the right plastic cable carrier is not just about managing cables — it’s about protecting your entire production process.

If you’d like, I can also:

- Optimize this further for SEO (meta title, meta description, schema markup)

- Add internal linking strategy

- Rewrite it for a manufacturer, distributor, or B2B audience

- Increase keyword density strategically

- Create a product comparison section

Just let me know your goal (traffic, conversions, authority building, etc.).

Add comment